Rhino HySafe has successfully completed full-scale testing on its ultra-fast explosion relief panels, as part of its inaugural Project UFER.

The company, which is a specialist subsidiary of Rhino Engineering Group, conducted the physical testing at RAF Spadeadam in Cumbria, following recent design and simulation tests.

The panels have been created to provide hydrogen refuelling stations, and other sites, with industry-leading technology designed to reduce the risks associated with explosions.

The full-scale tests demonstrated prompt panel opening, well ahead of flame-front arrival, and swift transition to a fully opened configuration, allowing unencumbered outflow of the flame-front and combustion products.

After the tests were conducted, complete retention of the panel elements was demonstrated, substantiating the design of the structural cassette and associated fixings.

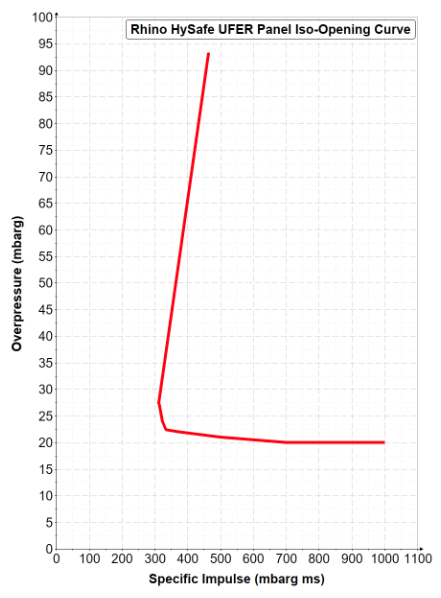

As shown in the below graph, the demonstrated performance envelope straddles the static, impulsive and dynamic range, illustrating the value of Pstat at 20 mbarg (0.3 psig), and minimum opening impulse of 325 mbarg·ms (4.7 psi·ms).

These properties, combined with a panel specific mass of < 6 kg/m2, ensure a rapid, low-inertia response following panel opening.

This iso-opening curve provides rapid insight into the UFER panel performance, independent of the explosion loading conditions of concern to the designer.

Following this successful explosion testing, Rhino intends to bring the UFER panels to market by March 2023, providing the global hydrogen market with innovative products for the protection of people and assets.

“After the success of our design and simulation tests, we had a lot resting on the panel’s performance during physical explosion testing,” said Stuart Lawrence, Group Managing Director of Rhino Engineering Group.

“Thanks to the expertise of our design and manufacturing teams, as well as a thorough research and development process made possible by Welsh Government funding, we have a marketable product which has exceeded our performance expectations.

“We’re now looking forward to formally launching the product to market in 2023, supporting global organisations to minimise the damaging effects of hydrogen explosions within a variety of commercial settings.”

Find out more about Rhino HySafe here.

Read about HySafe’s ultra-fast explosion relief panels here.

The Explore Export Wales event will showcase how the Welsh government can help Welsh companies with exports and trading overseas and the support they can offer businesses to help them succeed.

READ MOREStuart Lawrence, Group Managing Director and Jan McPherson, Group Commercial Director had the amazing opportunity to attend an exclusive a black-tie gala dinner inside St. Pauls Cathedral for the Make UK Manufacturing Awards 2023 on January 25, 2024.

READ MORE